Inspections and Controls

Benefits

Over the years, Cleanpart has established a broad range of control routines not only of its customers' components, but also for our internal processes, production environment and infrastructure.

This has led to

- Assured service quality

- Repeatable service results

- Predictive analysis

- Statistical process control

- Failure analysis

Properties

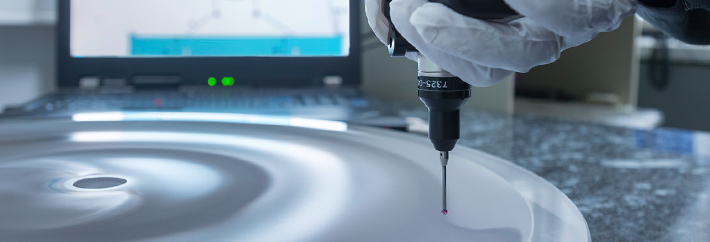

Metrology tools: ohm-meter, endoscope, optical microscope, roughness meter, 3D control, surface particles, LPC, deionized water resistivity and purity (down to 30 nm filter system) and dedicated test benches.

All Cleanpart sites are equipped with measurement and control equipment for maximum product characterization and optimized production management.

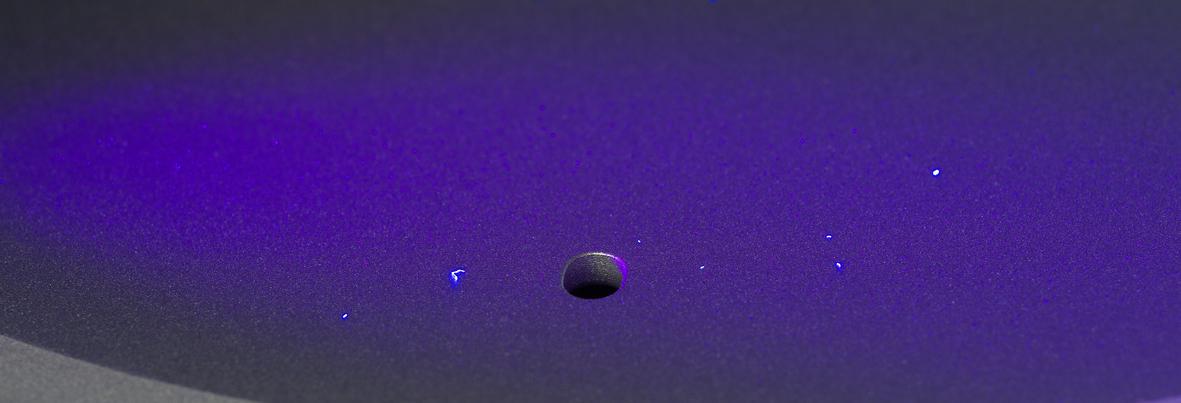

Various criteria can be monitored on or about our customers’ products. These include geometry/dimensions, roughness, porosity, contaminations (organic, anorganic, particles) and electrical properties.

Furthermore, customized tests and measurements with dedicated test benches can be performed.

Because we repeatedly see our customers' parts passing through our facilities, their proper characterization is a powerful tool to determine in which condition they are in and to predict where and when the appropriate action should be taken (refurbishment or replacement). These measurements provide the necessary data for component characterization, for issuing the Certificate of Conformance and troubleshooting. They are also used for statistical process control.

Inspections and controls complement our solid monitoring of online production infrastructure indicators. These include cleanroom parameters (hygrometry, pressure, particles – surface and airborne), temperature, DI water resistivity, LPC data and the production maintenance schedule for reliable operation of production equipment.

Overall, these indicators provide a comprehensive online analytical package that helps our customers improve their production tracking and forecasting.