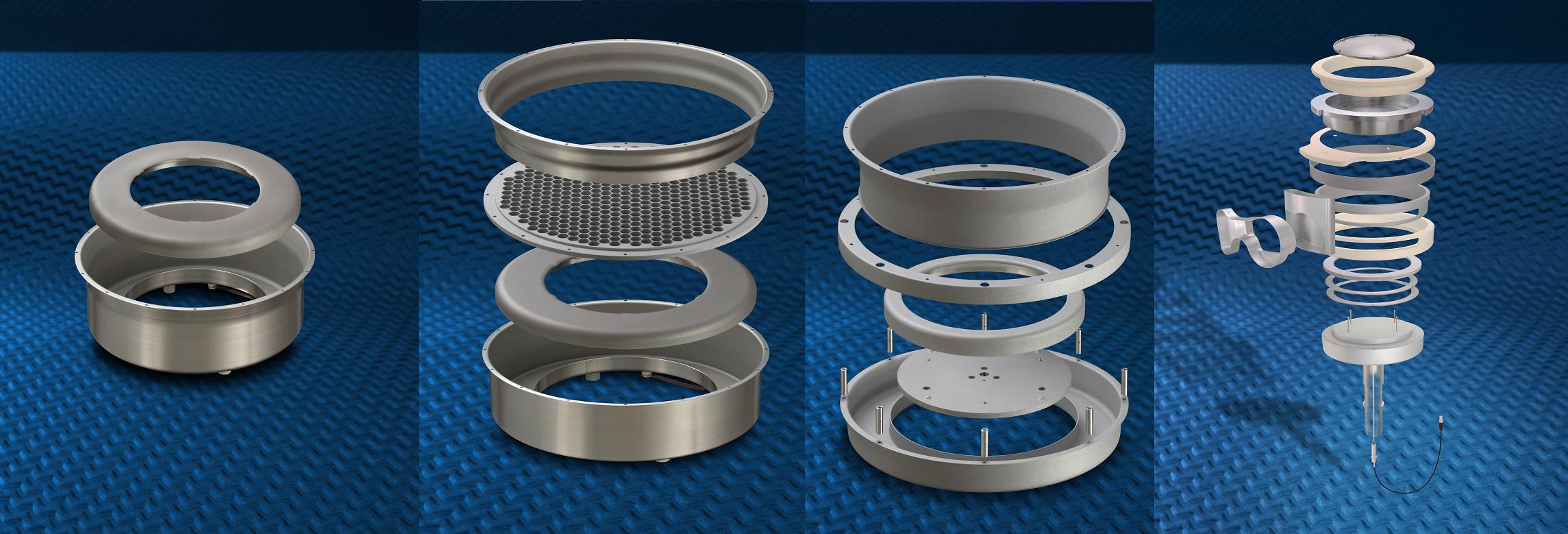

Spares Parts Manufacturing for Semiconductors

Benefits

To not only support our customers with high-end surface-treatment services, a separate business unit was established to manufacture parts. Our clear objective is to create the following:

- Improved design of spare parts

- Lower-cost parts than OEM parts

- Improved equipment performance

- Reduced cost of ownership for customers

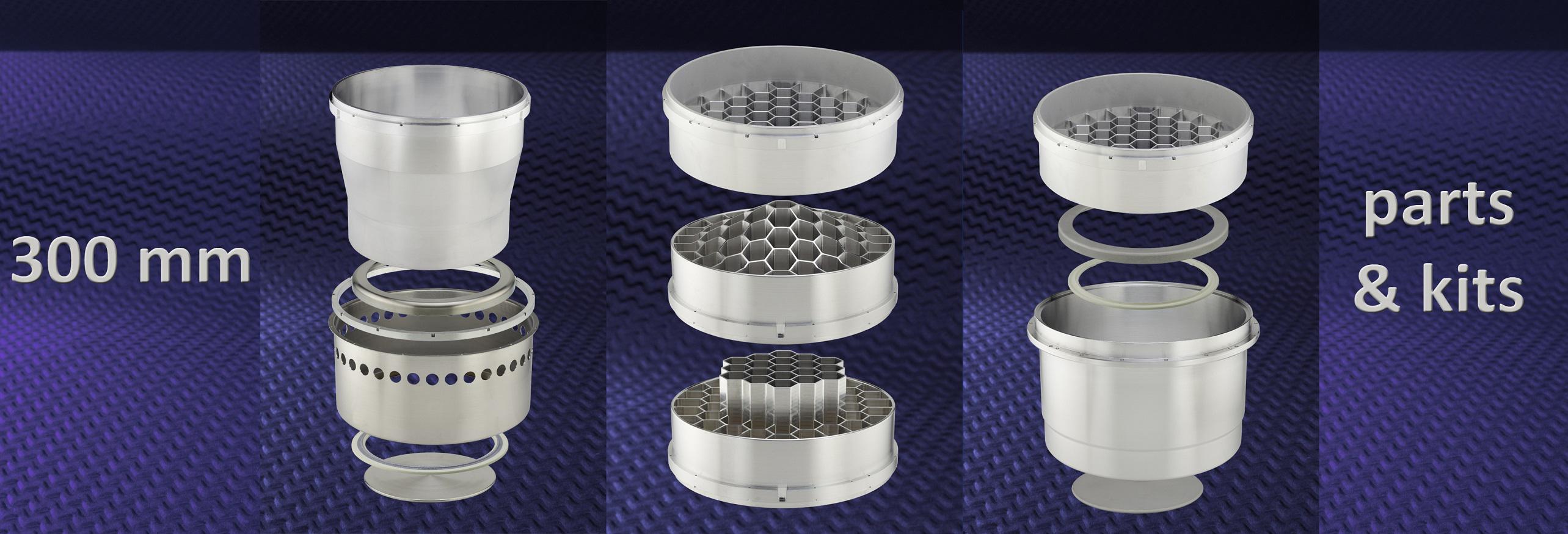

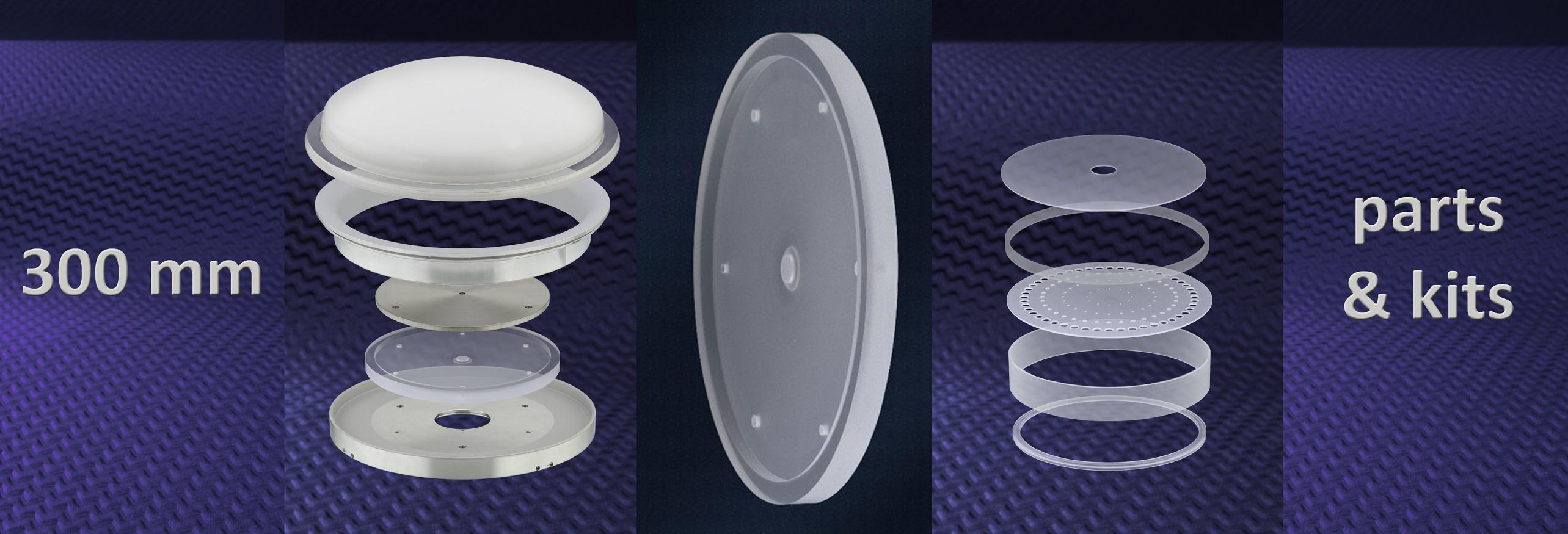

A large portfolio of proven and qualified spare parts is available.

Properties

- Spare part performance

- Cost of ownership (direct cost vs. performance improvement)

Cleanpart SET (Semiconductor Equipment Technologies) is a dedicated business unit within the group with its core competency in component manufacturing. This includes design, machining, surface processing, final cleaning, assembly and quality control.

Cleanpart SET usually works with customers on new spare part designs based on identified improvement concepts. Quite often, OEM parts can be improved with respect to tolerance, dimensions and overall design. Based on the performances as observed in the process chambers where the parts are installed, Cleanpart SET can implement a design change that will improve the performance of the reactor. This includes higher product quality, reduced contamination, fewer process interruptions, less damage to the customer’s products (wafers) and longer times between part changes.

Cleanpart SET offers a technical assessment of OEM parts followed by a (re-)design step using its own CAD and CMM tools. Cleanpart SET is able to manufactures prototypes and series with its in-house machining and surface treatment capabilities.

To provide ready-for-use parts, final inspection, cleaning and packaging is done under cleanroom conditions (class ISO 5) before shipment of the parts to the customer.

Cleanpart SET also offers complete inventory and spare parts management for any type of tool, including leasing models for special components or complete kits.