Cleanroom Control and Packaging

Benefits

Cleanroom control and packaging comprises conducting inspections and final packaging steps in a strictly controlled environment that ensures:

- Fulfillment of service quality and response time

- Repeatable decontamination results: ISO 5 specification for airborne particle density

- Guaranteed ultra-cleanliness of components up until their usage

- Comprehensive measurements available in a cleanroom environment

- Single component or complex component management (assembly/disassembly) in a cleanroom environment

Properties

- Cleanroom construction and operation according ISO 14644

- Metrology tools: 3D control, micro 3D control, surface particles, microscopes, blacklight inspection, etc.

- Well-trained operators

- ISO 14644 compliant/compatible cleanroom accessories

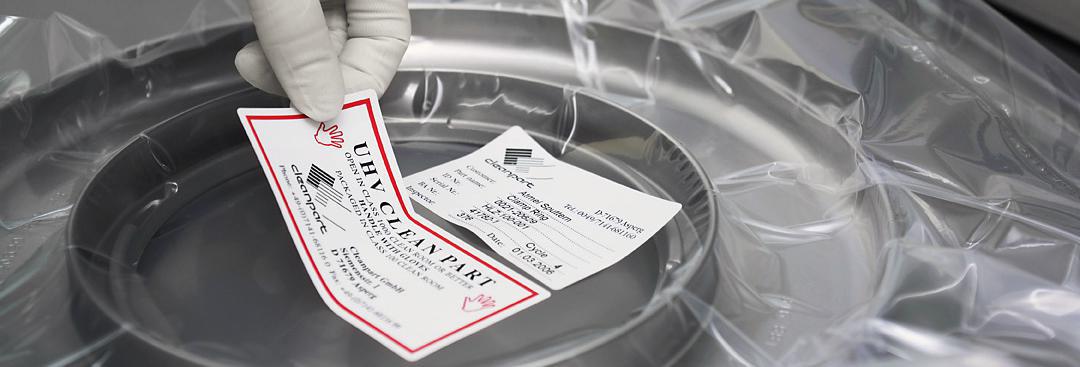

- Vacuum packaging units and dedicated ultra-clean packaging materials

All Cleanpart sites are equipped with cleanrooms according to ISO 14644, class ISO 5 (down to ISO3 in dedicated areas), where temperature, hygrometry, pressure and particles are tightly controlled.

Operators are well trained to follow a strict protocol. This ensures that our customers' products and components are decontaminated based on stringent specifications in an ultra-clean environment adapted to their applications (semiconductor, medical, optical, etc.).

Our cleanrooms have several measurement equipment devices to provide the necessary data for component characterization for certificates of compliance (COC), troubleshooting or lifecycle management.

Finally, all cleanrooms at Cleanpart have packaging capabilities to ensure that the products can exit the cleanroom environment in conformity with the cleanliness requirements and still be protected from the surrounding environment until they are used.