Surface Analysis

Together with material analysis, Cleanpart offers high-end surface analysis services for the semiconductor manufacturing industry that is intrinsically driven by material/surface interaction. Multiple surface characterisation technologies are used to develop new services, help customers in their process developments and production/maintenance challenges.

Benefits

- By using Cleanpart analytics capabilities, customers can acquire precise data about materials and surfaces.

- The obtained characterizations are used in multiple contexts – from qualification of new processes, new parts or new services to failure analyses, troubleshooting or yield/process/efficiency improvements.

- We deliver accurate and relevant data to sustain our customers' innovation or assist them in their operational tasks.

The Cleanpart engineering team is composed of skilled engineers and specialists in chemistry, material and surface science.

Cleanpart sites are equipped with their own laboratories for sample preparation and optical analyses, which are performed on various materials such as metals, alloys and ceramics.

We also work together with a network of partners, labs and universities that provides us with characterization means. Ultimately, we supply our customers with a comprehensive analytical capability tailored to their needs.

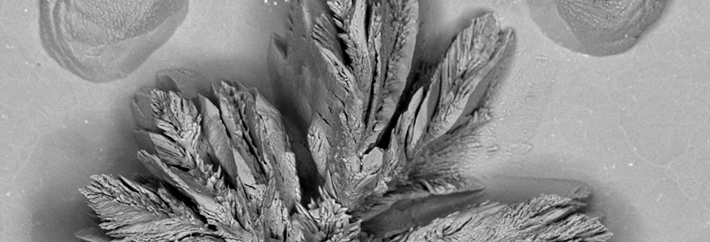

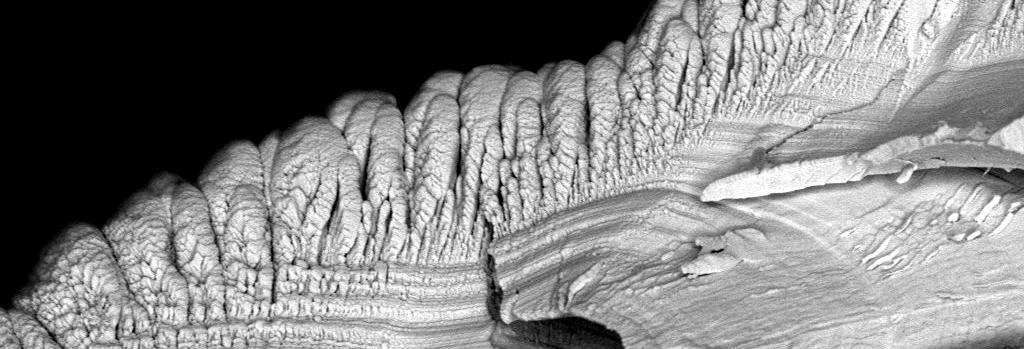

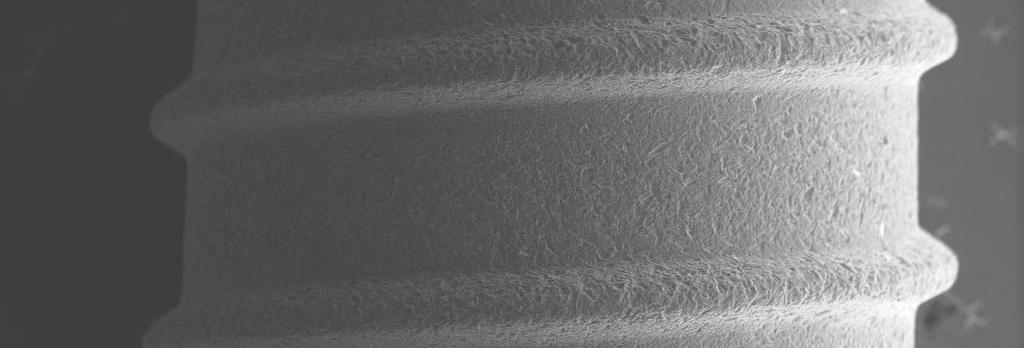

- SEM: scanning electron microscopy

- XPS: Auger spectroscopy for trace contamination detection

- AFM: atomic force microscopy

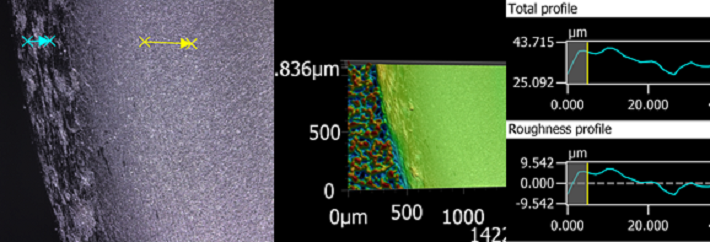

- Optical profilometer 3D map construction of the surface of materials

- Analysis capability down to a nanometric scale

- Suitable for all type of materials: metals, ceramics, plastics, conductive or non-conductive materials